Bits and pieces ready for the rad frame to be installed.

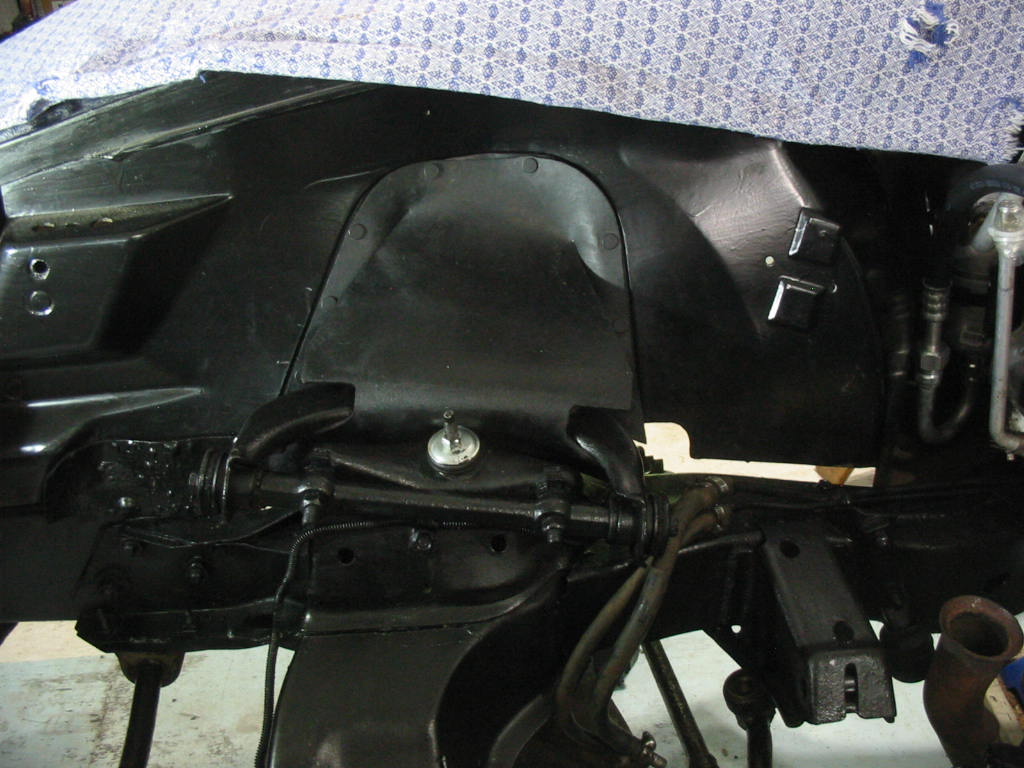

Rad frame back in. It’s a bit of a tight fit and I’ll be painting over some scrapes on the fender aprons! Other wise ready to install the AC condenser and the new radiator.

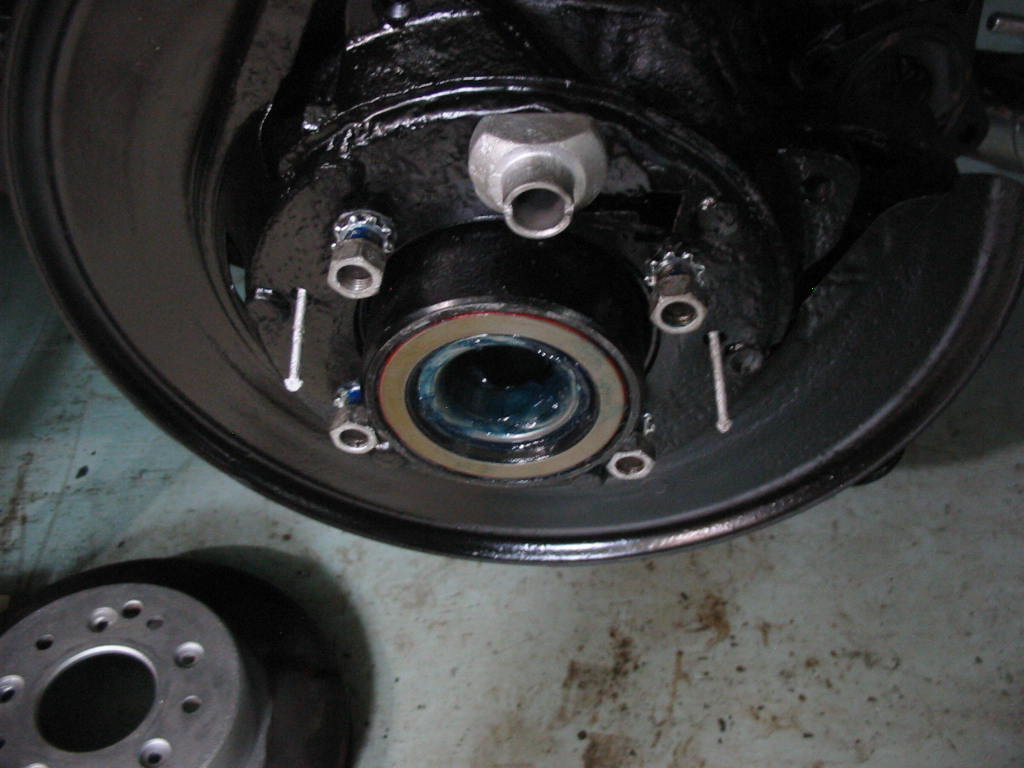

A new ‘fail safe’ 195 degree thermostat. A bit of red sealant to make sure there are no leaks from flaws in the metal.

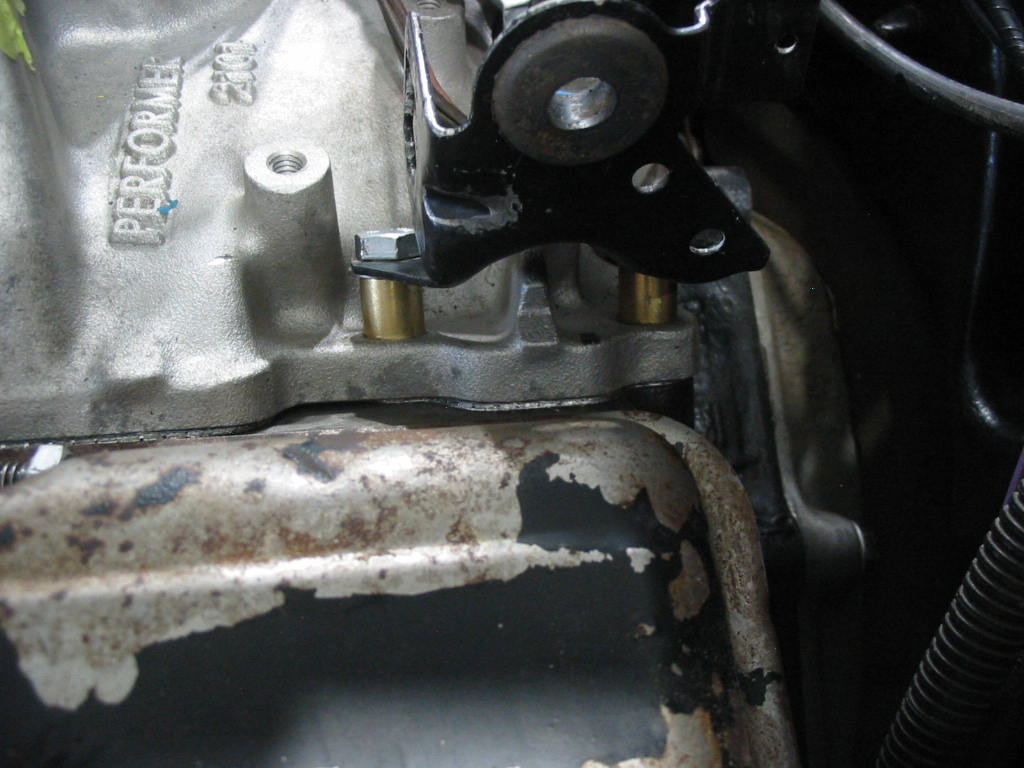

Not the original outlet, but rather a new unit used on older engines without the modern emissions fittings. A neater look and I have disconnected the EGR and the cold weather warm-up systems (the under manifold heater and the warm air induction system from the manifold to the carb via the air cleaner). I’ve snugged up the bolts by hand and will torque to spec in a day or so.

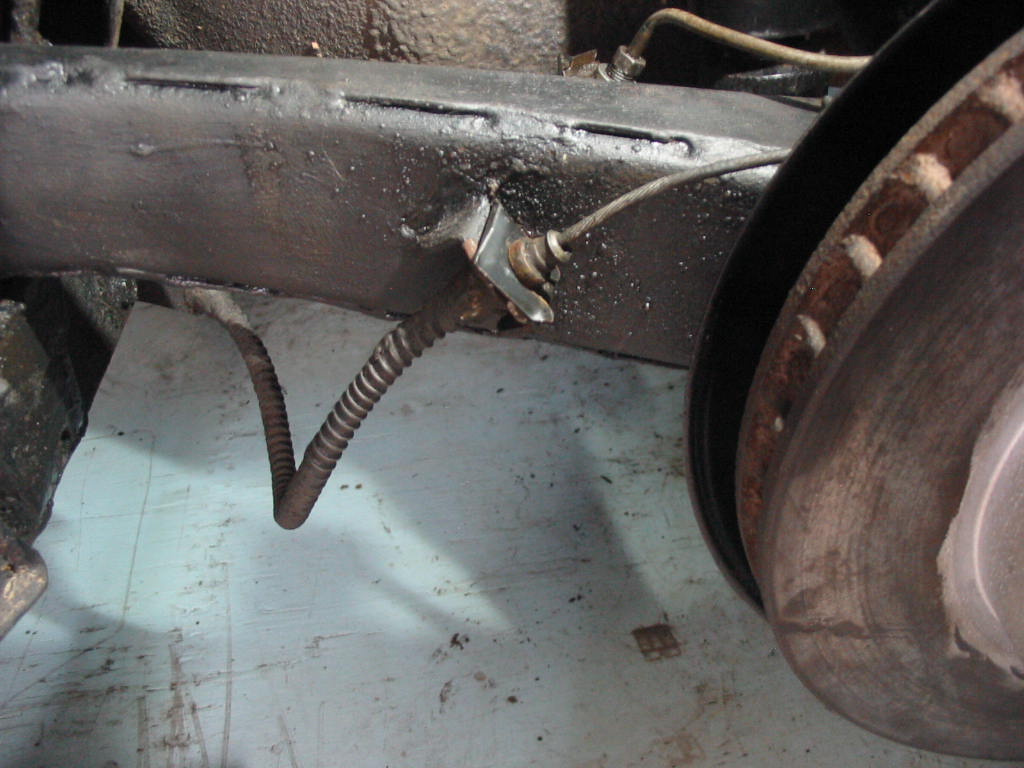

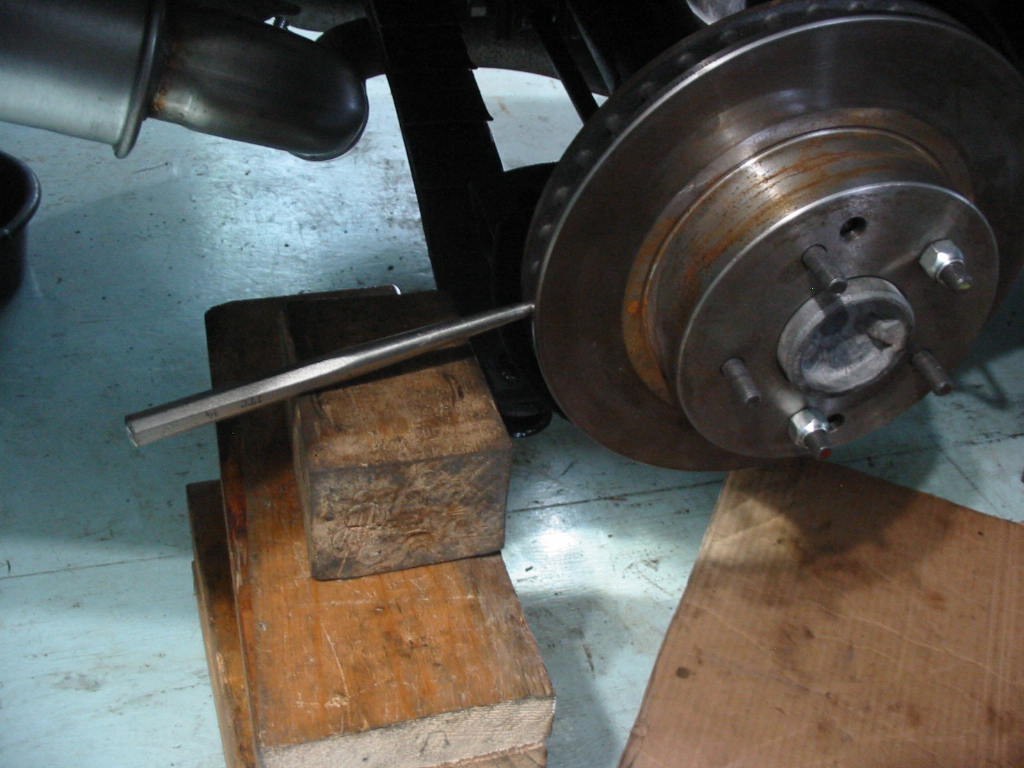

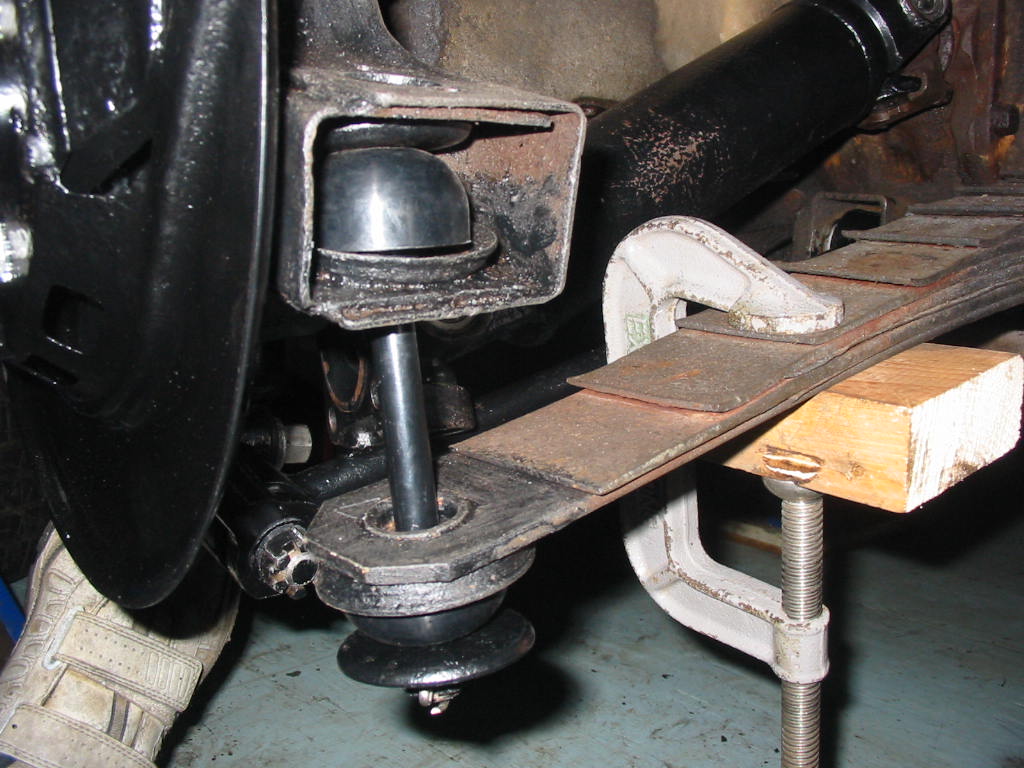

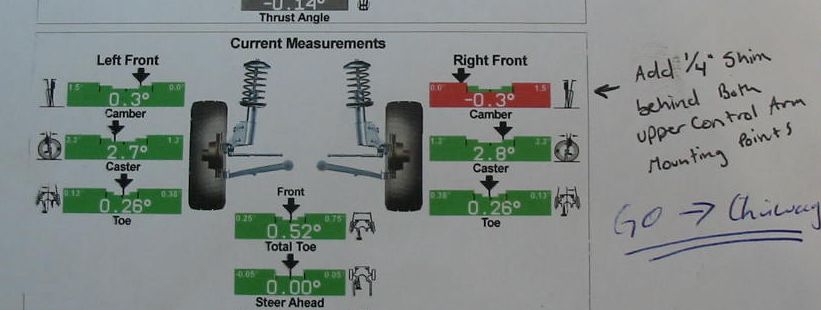

The alignment shop (OK Tire) could only set the toe on the front end. The caster was OK, but the camber was out. They wouldn’t attempt to change the shims to get it in line. The alignment tech did note what it would take to get the right front tire aligned.

Even though the tech wrote ‘add shims’ shims actually need to be removed to adjust the A arm outward to move the camber from negative to positive.

Fortunately there were four 1/8″ shims that could be removed. Two from the front and two from the rear.

There are still some shims at both ends. I torqued down the bolts to spec and all should be OK. I will still need to do an alignment as I have changed all the bushings in the rear suspension. It will likely now be out of spec. Another $100 to the alignment shop!

Movin’ along, the AC condenser is in place.

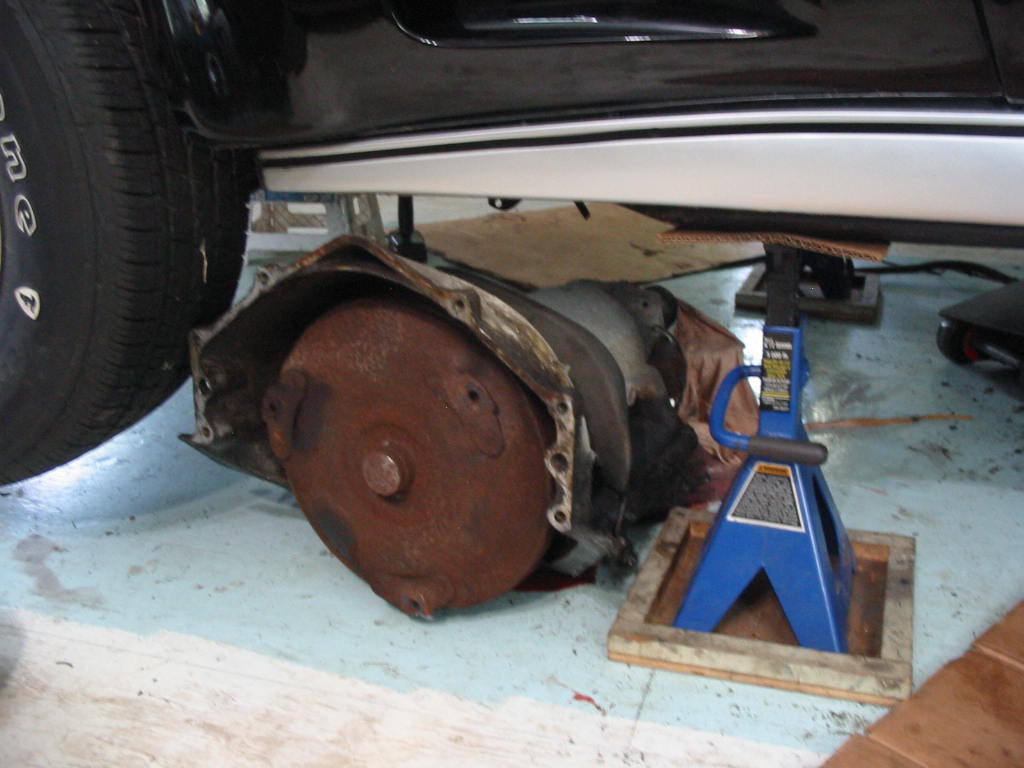

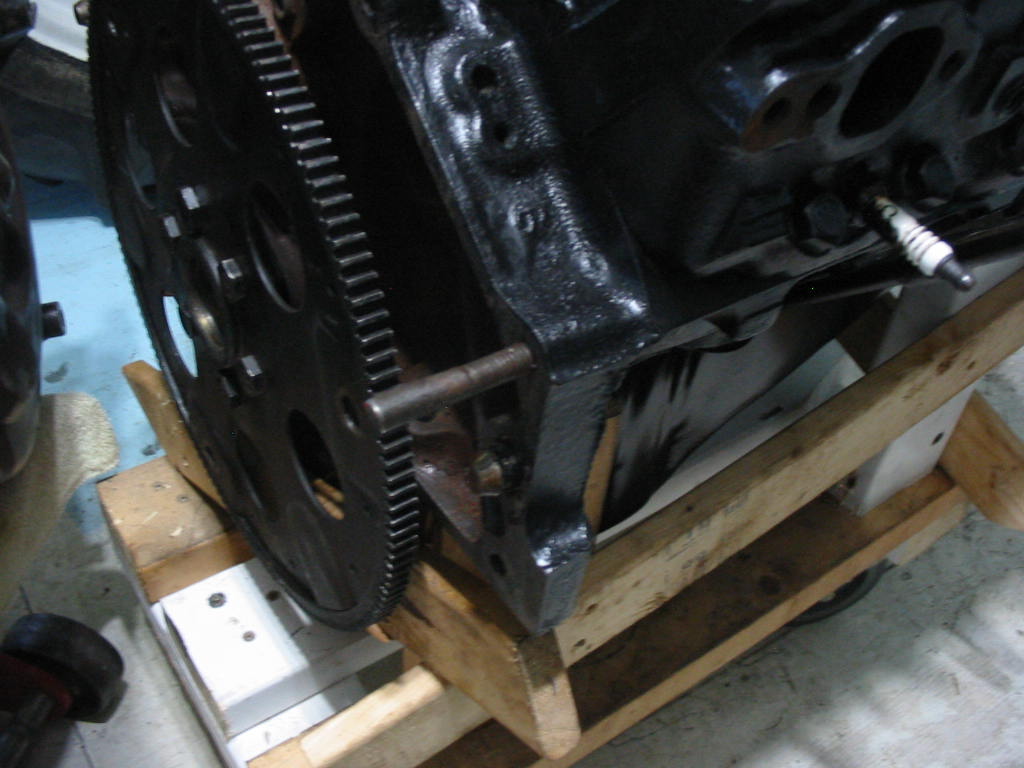

Next: I will be putting the power steering pump and front crank pulleys in place before fitting the new rad. In the meantime I’ll go underneath and bolt the flex plate to the torque converter and get the trans cooling lines in place.