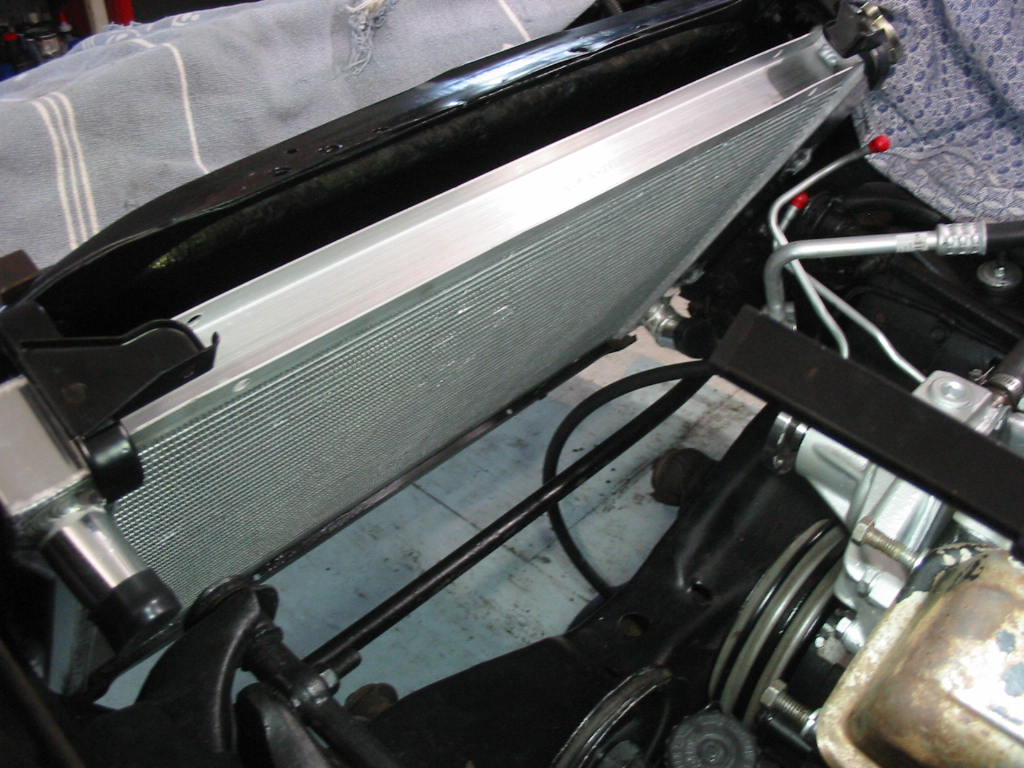

New rad nicely in place. Then I tried to fit the fan shroud….

The rad had to come out again before I could get the shroud in place. It’s also the best time to install the fan pulley and fan. I’m going with a flex fan as they use less HP at speed and provide good air movement at idle. I’ve read you can gain 5 hp with them. That would cover the loss from the AC. I’ve yet to sand the fan pulley. I’ll use a short length of V belt and course sand paper to clear out the grooves.

Lots of bending and twisting to get the trans cooling lines close to where they need to be. I was supplied with a 90 degree and a straight fitting to make the radiator attachment. Turns out I needed to use a 90 degree fitting in both places. I also had to cut off a section of the output line. Here I’m using my double flare tool to make a bubble on the end of the line.

Works quite well if you just go a bit easy on the first step and don’t go all the way. The second 90 degree is visible on the right of the photo.

Both lines hooked up and ready to go:-) Not as neat as I would like and one reason I paid for custom lines! Not a happy camper about that.

Installing new studs in the exhaust manifolds. I have put never-seize compound on the threads just in case I need to remove them. I’ll also put the compound on the bottom threads as I will need to take the engine out in a year or so

.

The bottom gasket came with the new exhaust manifold. The top ones are Fel Pro and they are easier to put in place.

Next: getting the exhaust system in place.