Once again I’m out of sequence. Hope this all makes sense.

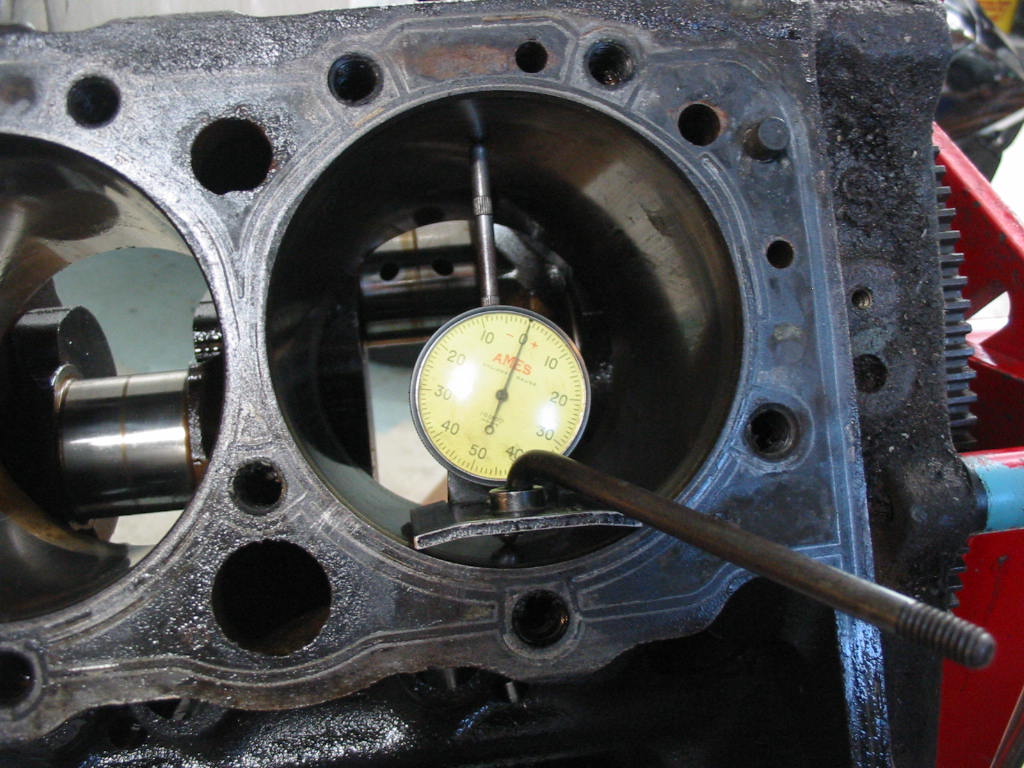

Arnold Legrow an old mechanic who passed away some years ago, knew I was interested in engine building and he kindly gave me this handy tool I can use to measure cylinder taper and bore out-of-round. The taper limit is 0.002 – 0.003 and all the bores were 0.002 or less. The out-of-round came to less than the .014 for 4″ cylinders based on 0.0035 per inch of bore. So all OK with the worst being 0.002 at the top of cylinder #7.

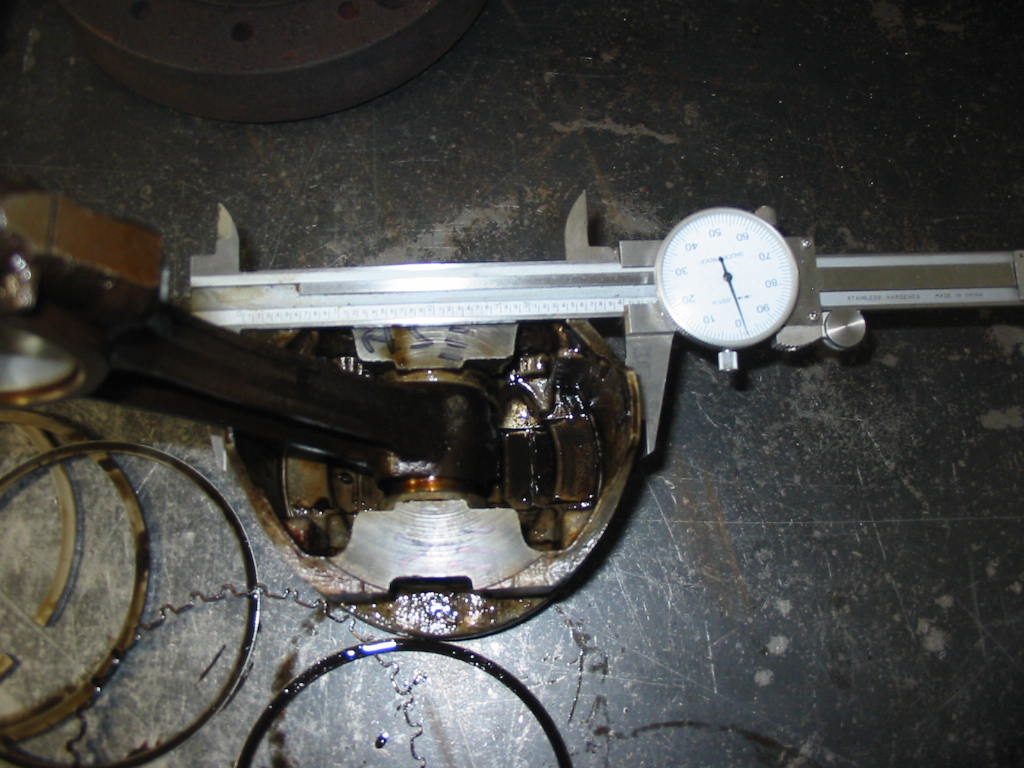

The pistons measured 0.002″ under 4″ so standard pistons. This is all very confusing since the car is supposed to have 144k km! Either the engine has been changed at some point or the car really only has 44k km. The block still has the remains of the GM corporate blue paint on the block that was correct for the ’79 models. The car supposedly sat for 20 prior to 2022 so it was only driven from ’79 to 2002 or 23 years of driving which is a long time to put only 44k km on the dial. So all very confusing and I’ll likely never know the history as I don’t have the contacts to check.

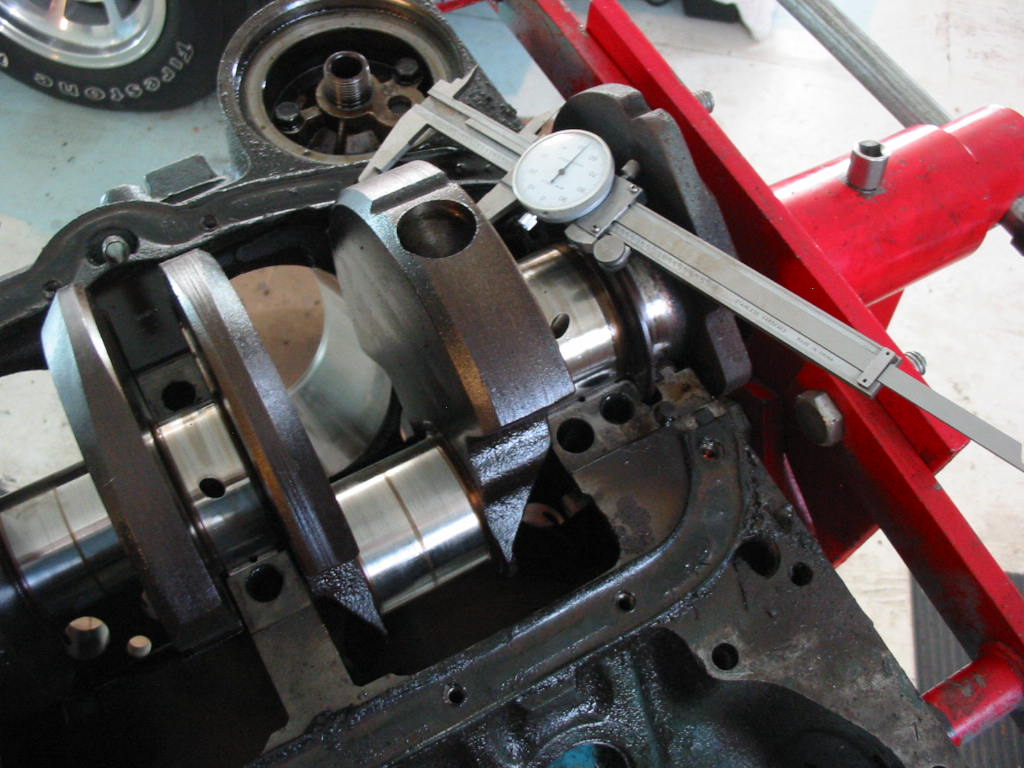

My machinist caliper is only a 2″ unit so I couldn’t use it for the crank. But the best I can figure is that the rod journals are standard at 2.1″ and the mains at 2.447. So good news here. So far it looks like an engine block refresh only needed. I’ll change to flat top pistons and also install a slightly better camshaft. and new lifters.

I’ve decided to remove all the frost plugs. The last thing I need is for one to start leaking after I have the engine back in the Chevy. They are all showing some serious pitting on the inside edge of the lips. I had to use an old piston pin – it has a sharp edge – to rap on the outside lip of the frost plug to get them loose. They tended to fall into the block, but were easy to take out. When I tried to tap on the inside of the plugs they just split.

Meanwhile I’m still trying to get the bugs out of the 305 install. One issue is that the original vacuum switch and vacuum delay aren’t working as I would like. The Chevy locks up too soon after going into 3rd gear.

The problem I think is in the vacuum delay unit. These are, as my friend Jim Bartley says, unobtainium – no longer being made by GM. I looked at a number of replacements, but couldn’t be sure they would work. I came across this unit which says it is for non-computerized transmissions like the TH350c, 700R4, etc.

It doesn’t have a vacuum delay, but rather works by the level of vacuum coming from the intake. It can be adjusted up or down to suit the application. I’m thinking that setting it for a bit higher vacuum will delay when it engages thus allowing the car to speed up a bit more in 3rd before engaging the lockup. I had to make up a little aluminum bracket that I was able to mount in the holes I had made in the firewall for the original setup. the switch can turn on current or turn it off. I will run power to the unit and choose the connection to allow current to go to the trans when vacuum is applied.

Before I had to take the 305 off the road I did manage to see how the new lock-up switch worked. It is pretty good with its original setting. It delays some before going into lockup. I’ll increase to vacuum level a bit when I get the Chevy on the road with the rebuilt 350.

Next: more on the 305 engine removal