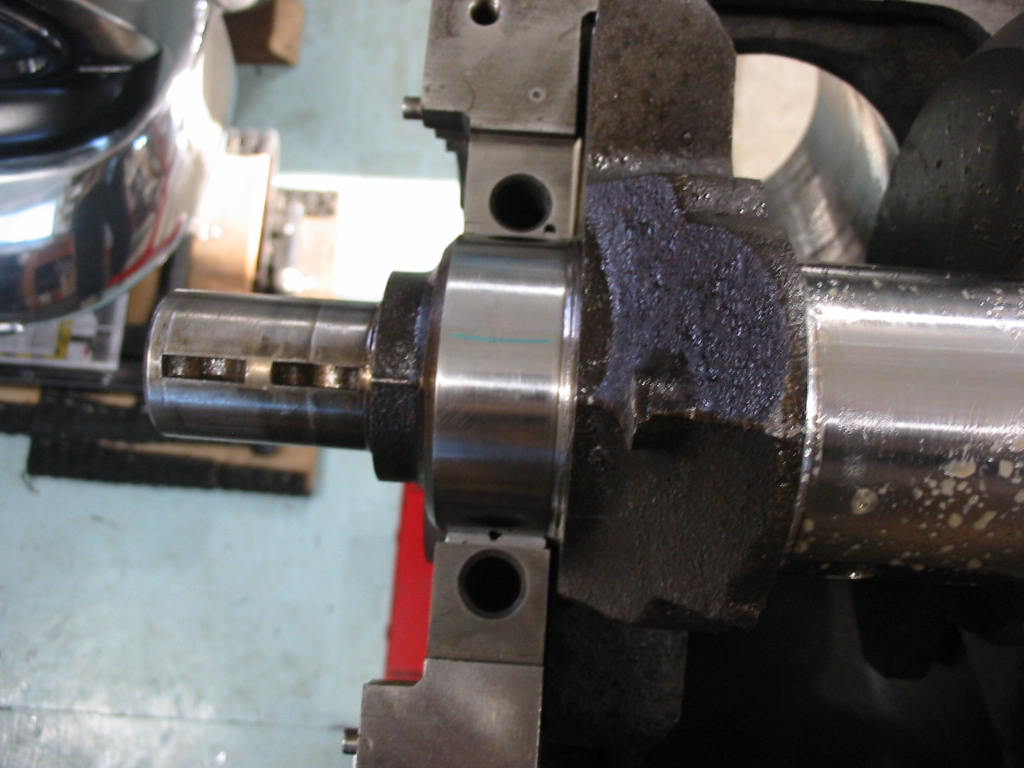

I wiped the mains before setting the crank in the block on new bearings.

I put a short strip of plastigage that can measure between 0.0015 and .003 on each main.

I then put all the main caps in place with the new bearings and torqued them all down to 80 ‘#. I measured each and I came up with between 0.0015 and 0.002 for numbers 1 – 4 and 0.003 for the rear main. So all withing GM spec 🙂

Main bearing caps in place. Best way to avoid damage to the new bearings. I’ll leave the crank out until the new cam arrives. It will help to have access to it from inside the block so the chances of bearing damage is minimal. So waiting on Rock Auto now.

Next: Cam and crank