This is my gizmo to test valve spring strength. The arm is held in the vice with a bolt acting as the fulcrum. The block below the arm on the right limits the about of squeeze on the spring. The scales aren’t all that accurate, but I’m only interested in singling out the strongest. Each spring is placed in the same spot and the arm is centreed over the spring and it is compressed the same amount.

I tested the original Chevy springs as well as the ones from the crate engine. The range went between 66 and 100 lbs. 16 of them were in the 90-100 lb range and that’s what I’ll use in the engine. They will not be good for high revving, but I will likely only ever get to maybe 4000 and that in passing gear.

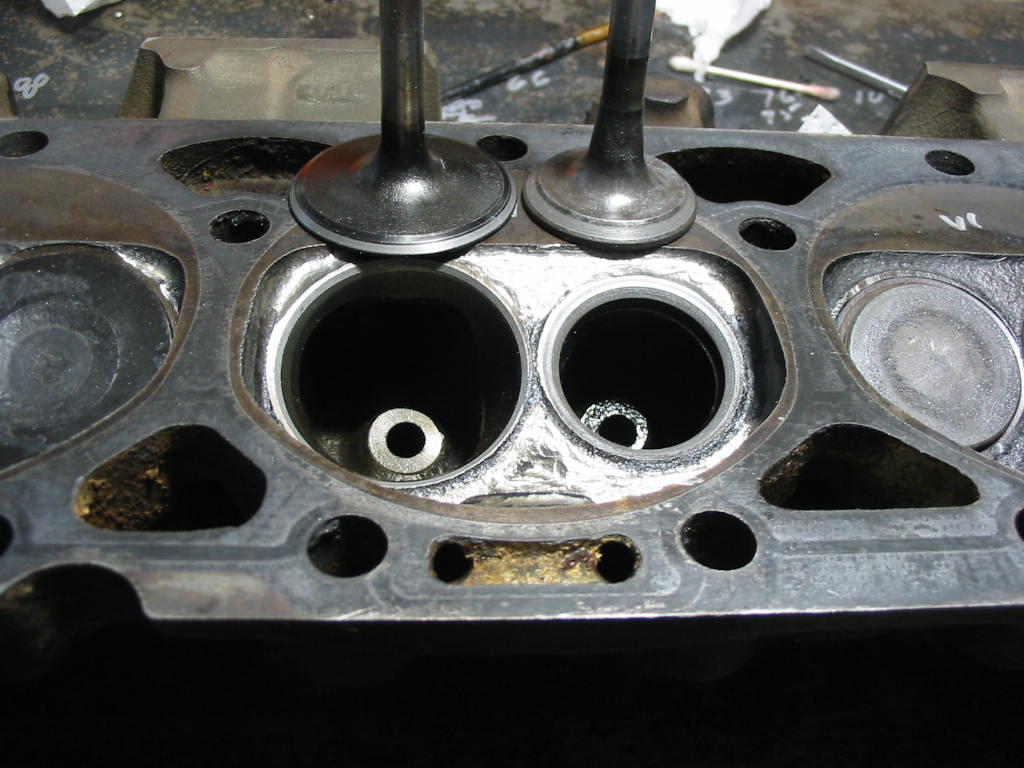

The next job to be done was lapping the valves. I used Permatex valve grinding compound and a lapping too adapted for my drill. I coated each valve and seat with the compound and then ran the drill forward and backward twice. Lifting the valve and setting it down 6 times each way with a bit of a delay between each lift to allow the compound to do its job. I only needed to do this routine once for each intake, but twice for each exhaust valve. The result was not perfect, but pretty darn good with next to no tiny pits showing on the valves. The seats all seem to be perfect.

Another trip to the parts washer for the heads and valves to remove all vestiges of the grinding compound – it’s pretty fine stuff and would mess up the valve guides if it remained in the heads. I was careful not to get it in the valve guides while I was doing the lapping.

Next: Putting things together