Tomorrow looks like an above zero day and good for startup. In the meantime…

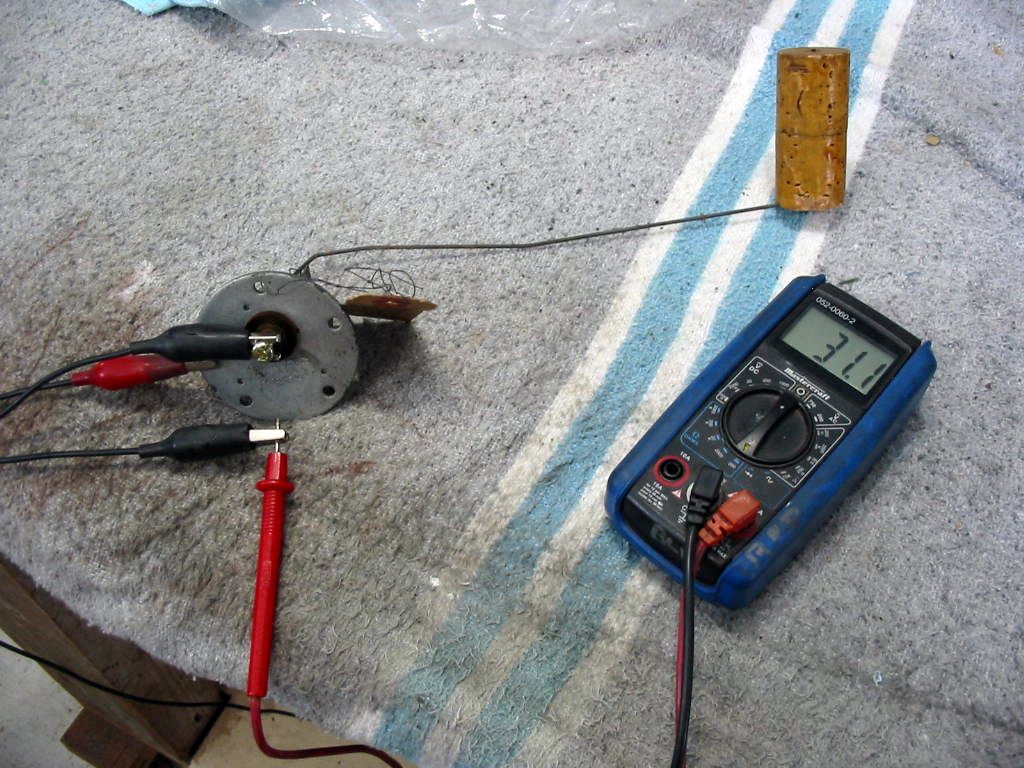

The gas gauge on the ’66 Commander is a bit wonky so I decided to pull the sensor and check it out. Not to hard to get at though a hole in the trunk floor. Studebaker used good steel in their cars. After over 60 years the screws came out very easily. Copper washers under each screw helped. The clamp is holding the sender connection so I won’t lose it between the tank and the underside of the trunk floor.

This is a new sender that I had in my stash of parts I saved from my Studebaker inventory that I parted with a couple of years back. It checked out OK, but when I connected it to the gauge in the dash it was OK on empty, but not on full.

This is the original sender. I ended up cleaning it out with electrical contact cleaner and compressed air. After that it registered empty and full OK on the dash gauge. Rather than try and scrape off the original gasket that is stuck to the tank I coated it with Permatex gasket sealant and reinstalled the sender. It would have been hard to get the old gasket scraped off without getting some crud in the tank. The part of the tank that is visible through the sender opening is nice a clean 🙂 The camera flash makes the metal on the sender look odd. It is also nice and clean. If the gauge still is wonky it might be that the cork float is saturated and not keeping to the top of the fuel. If it is I can swap the float with the one from the new sender that I have or buy a metal replacement.

Today is the day to start the engine and do the break in run.

First step: using my drill on an oil pump spinner.

Next I attached the two exhaust pipes to the door outlets. I’ll use this for start up and when it’s going I”ll open the garage doors as there’ll be a lot of fumes. I have also opened windows and the trap door to the attic.

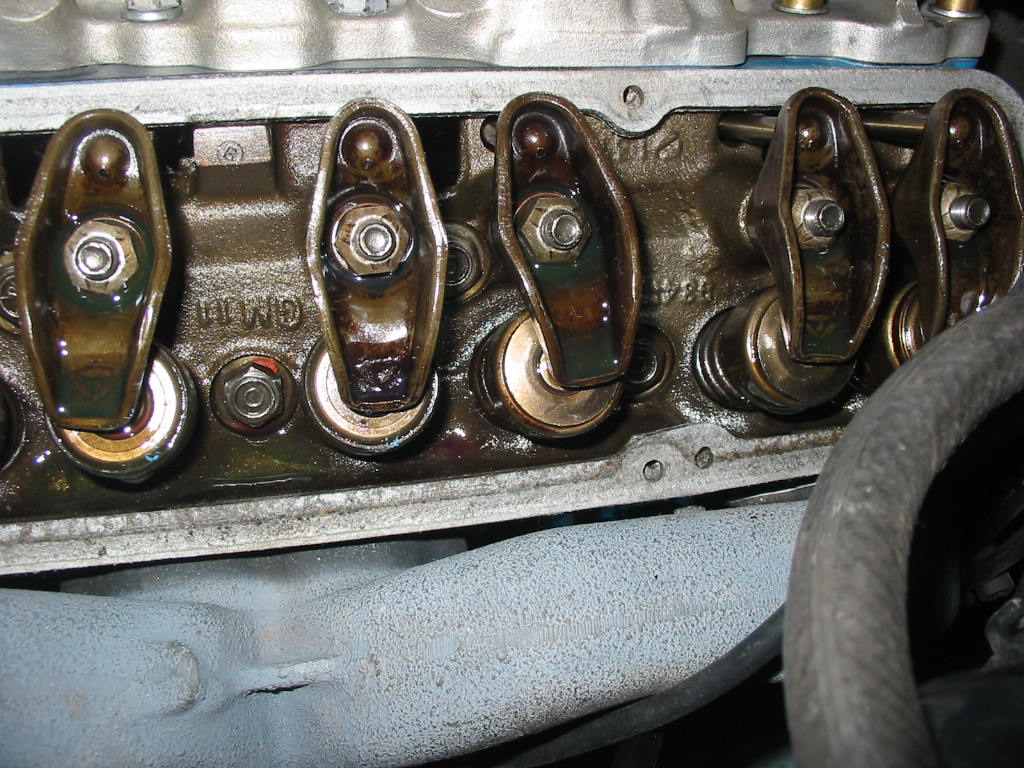

I ran the oil pump spinner until I got oil out of all the rockers. Didn’t take too long as the spinner created 40 lbs of oil pressure.

Hooray the engine started right up. No mixup with the wires or bad timing 🙂 I ran it for over 20 minutes between idle of 800 rpm and 1800 rpm. Two problems did crop up.

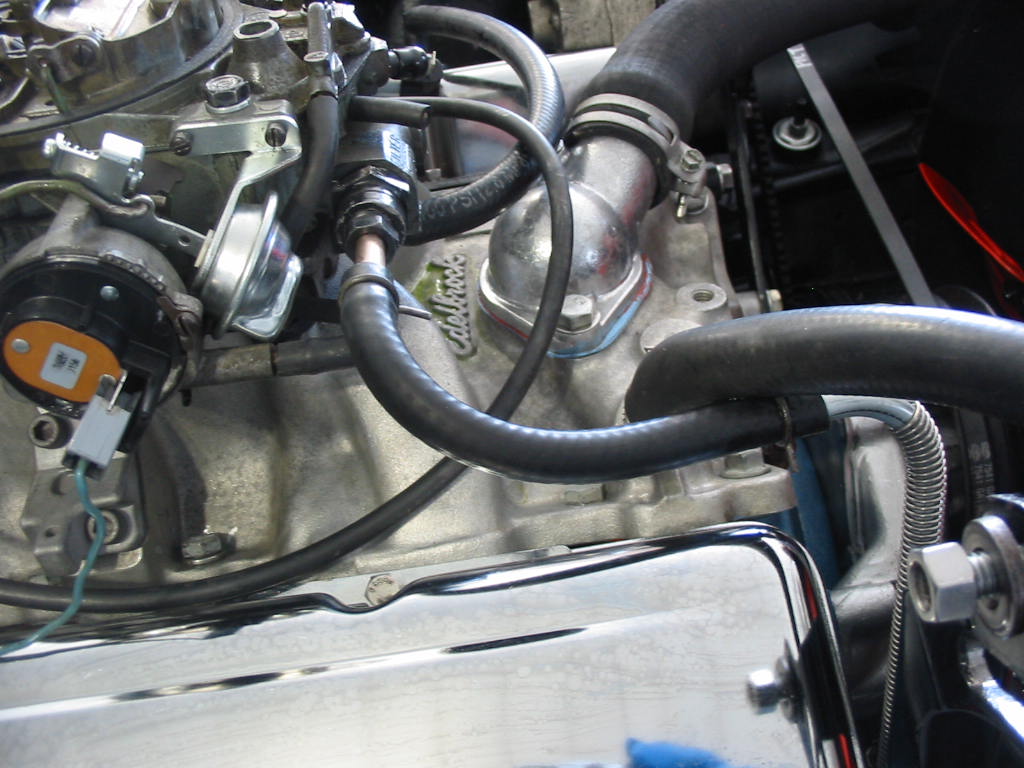

The fuel line at the carb leaked. I overtightened it and it still leaked. This is my $30+ nice new steel fuel line that I had to bend to fit and now I had to cut off the top of it and replace it.

Fortunately I had a bit of copper/nickle fuel line of the right size with the proper end. I put it in the double flare tool and just started the first of the flaring process which gives a nice bubble on the end of the line to help sealing. I did it also to the end of the steel line I cut off. Now I only needed a couple of spring clamps to get a good seal. After this there was no leaks!

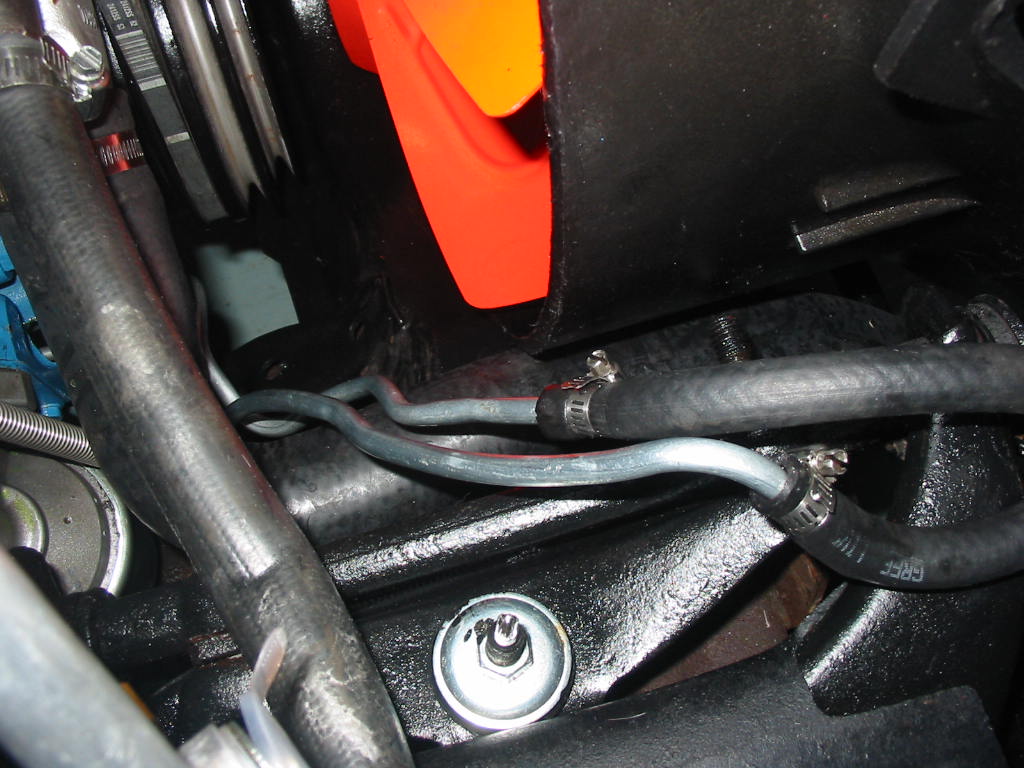

The second problem arose when I added oil to the trans to top it up. The trans was rebuilt so I couldn’t get all the oil needed on startup. Once I added enough oil it started to pump through the radiator cooling lines and unfortunately I did have the gear clamp on one of the lines tight. There is a bubble on the end of the line from the trans, but hot oil under pressure was just too much for the connection. It is right behind the fan so oil got sprayed everywhere even to the top of the windshield and over!

My car cover was piled on top of the car so it too got a smear of oil. Hopefully the sudsy rag got it out. If not I’ll take it to a laundromat and use an extra large washer to give it a going over.

Next: now I can go ahead with getting ready for the road.