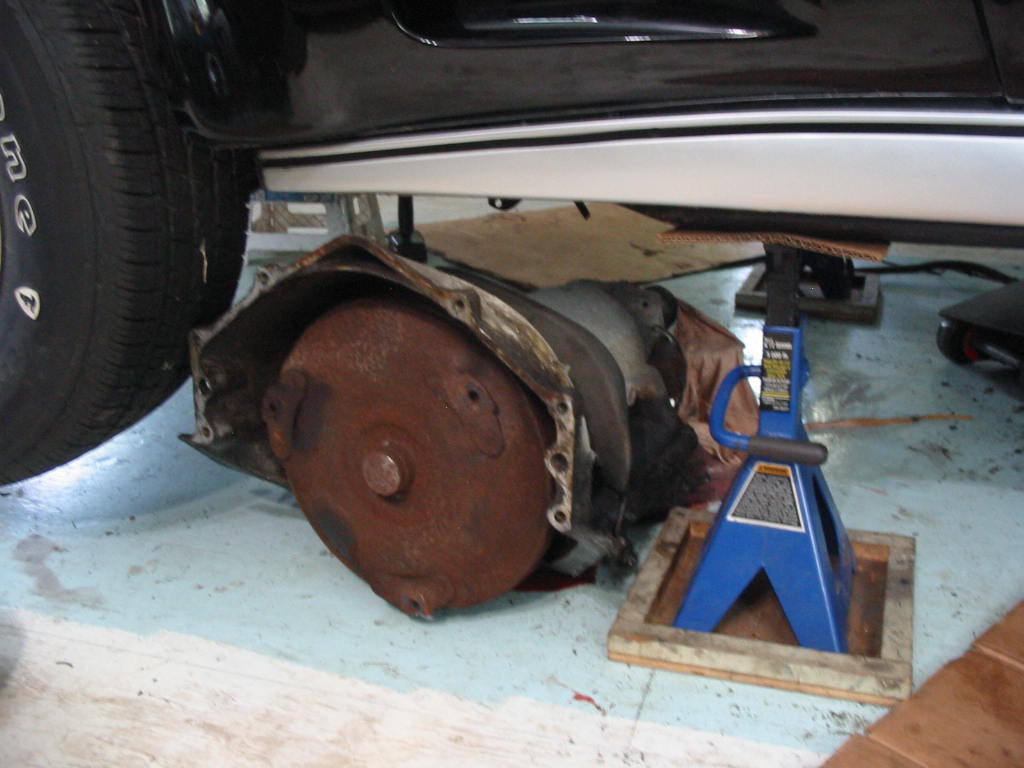

The trans on the jack won’t fit under the car. So it has to come off and be slid out. I could jack the car up to take it out on the jack, but I would have to raise the car a lot and then go through the whole process to get it back down.

In the end I just slid it off the jack and pulled it out. Lots of trans fluid everywhere. Next time I’ll drain the trans while it’s still in the car! Why GM don’t put drain plugs in the transmission pan i don’t know???

Donor trans on the jack and ready to be connected to the engine. I have decided to attempt putting the trans and engine back as a unit rather than do it separately. Hopefully my 8’ceiling will will allow me to get the engine/trans high enough to go back in as a unit.

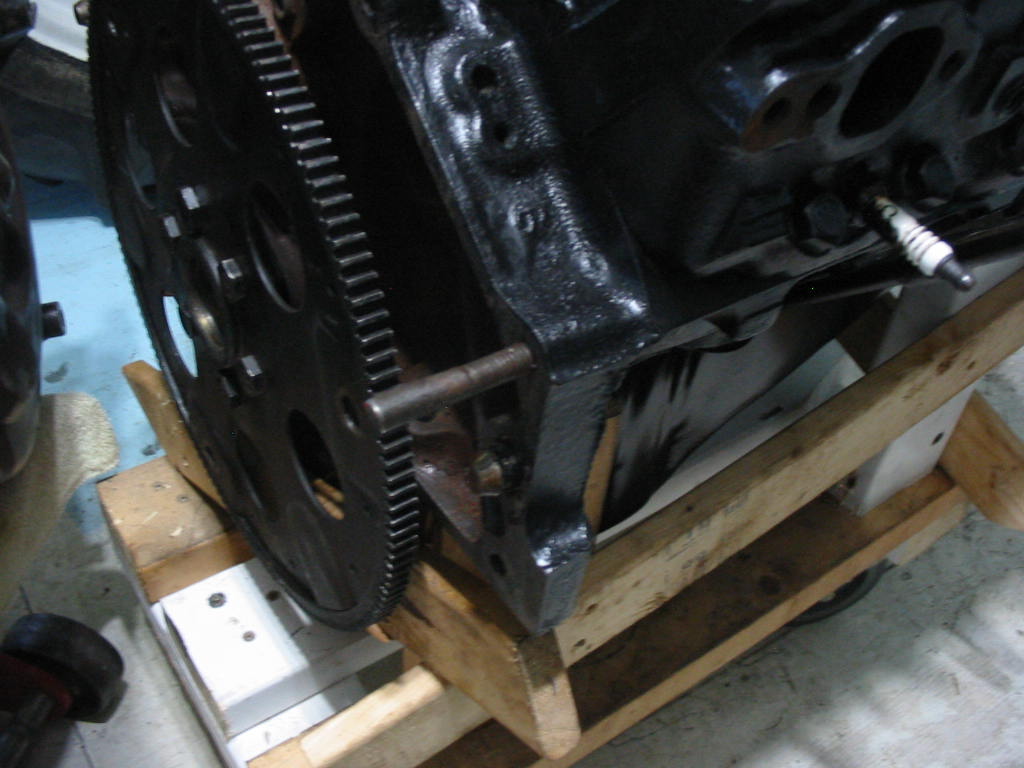

I’ve put a couple of pins in the block to help line up the trans for assembly. The factory alignment pins are short and it is hard to keep one in place while trying to fit the other. these longer pins work better. Get the trans on one pin then use a small vice grip to hold the trans on the pin while getting the other in place.

The engine stand was too wobbly so I did the job on the floor holding up the engine with the hoist and lining up the two that way.

Engine back on the stand and a little support for the trans. I’m in the process of transferring the modulator, speedometer gear, shift lever, etc from the original trans.

Next: back to the rear suspension.