High pressure line connection to the orifice tube. The low pressure switch is a bit tight but it will work.

The low pressure line at the condenser is a bit pinched. I cured that by releasing the connection a bit and twisting the low pressure pipe until the kink was pretty well gone and then re-tightening the connection.

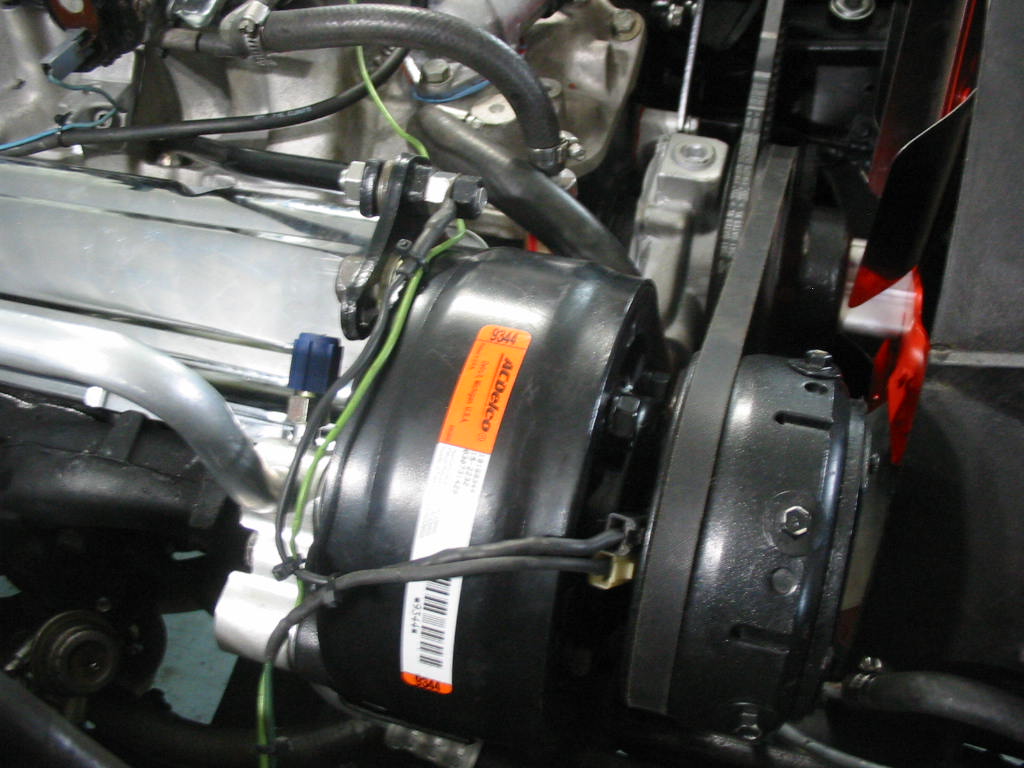

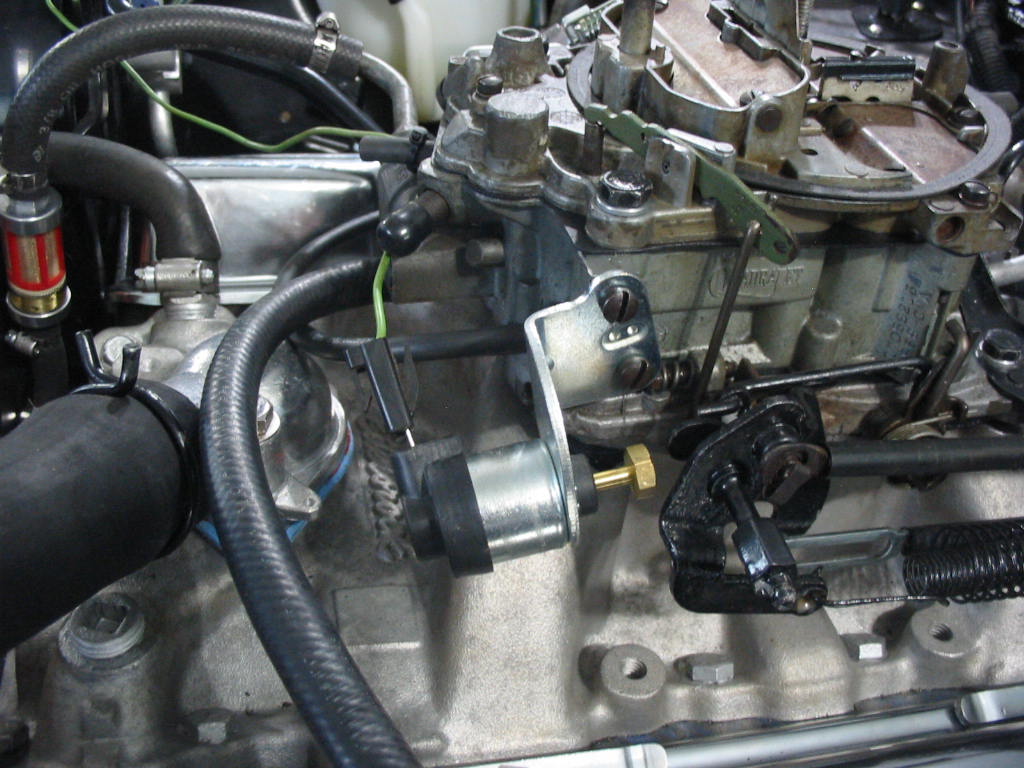

Ground and power leads connected with the kicker switch line travelling off to top of the photo

New throttle kicker switch in place. It will up the RPM by 100 when adjusted and the AC is on.

Time to tighten the rear struts. They have new bushings and need to be torqued while the weight is on the wheels. I’ve put a couple of layers of hard plastic on top of the wood blocks. This should allow the wheels to spread out and put the suspension on its lowest level.

The inner strut fastener was too close to the exhaust pipe so I couldn’t use a torque wrench. It calls for 65 ‘# so I gave it a good pull with a wrench and a wrench extender.

The lower connection needs 75’# of torque which is a bit of a bear to get in the small space for the torque wrench to swing. I chose to go to 65 ‘# and a bit more to get the cotter pin in place.

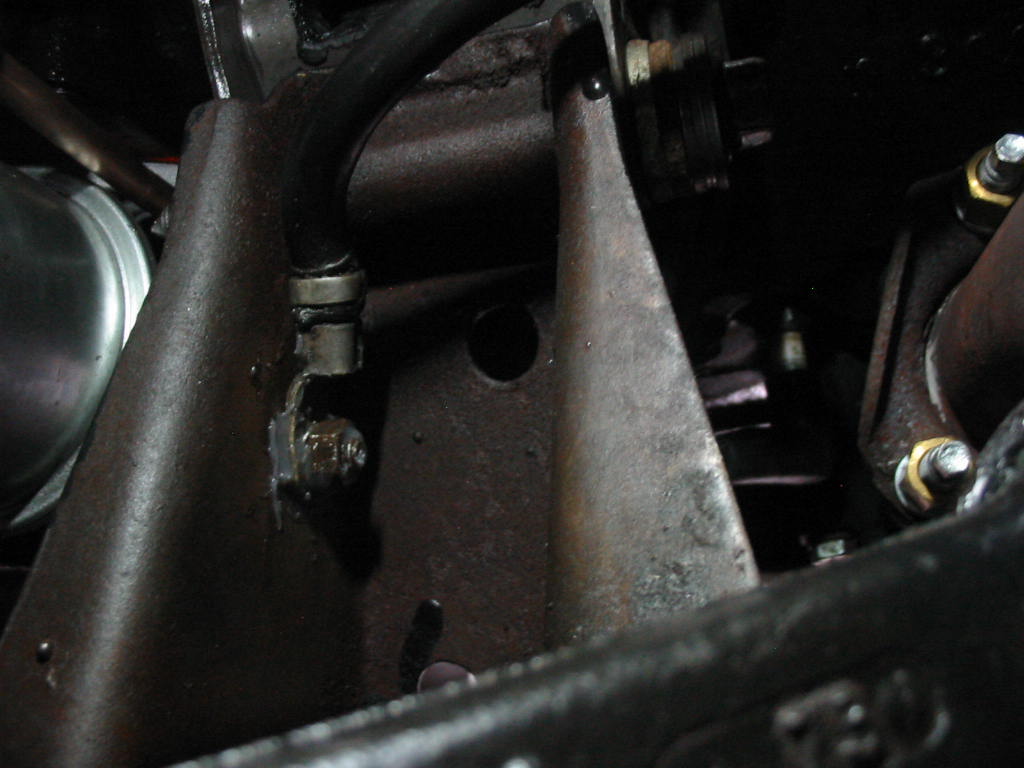

Last job underneath was to install the large ground wire from the frame to the engine block. I’ve smeared some dialectic grease over the frame contact to keep the corrosion away.

Next: Getting close to being back on the road!