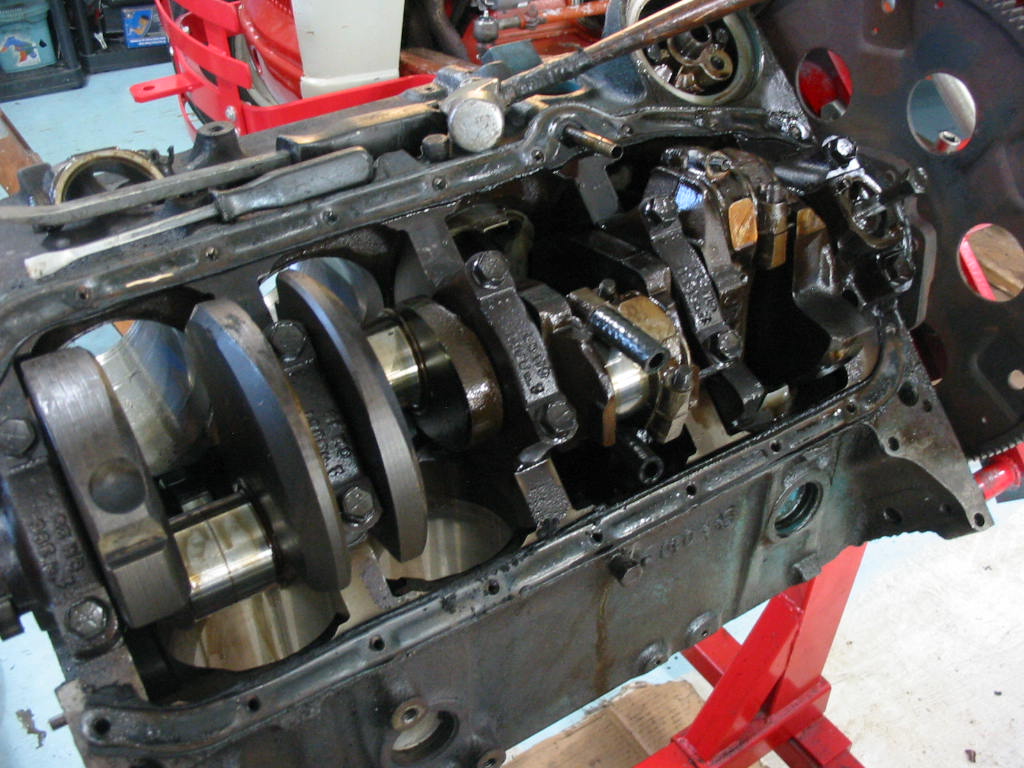

Ready to use a reamer to remove any top-of-cylinder ridges so I can get the pistons out. The paint wheel on the drill was good to remove any carbon deposits at the top of the cylinders -without damaging the cylinder wall – so I could see how thick the ridges were.

Surprisingly for an engine that is supposed to have 150k km on it there was virtually no ridges at the top of any cylinder. All the pistons came out easily once the carbon was removed with the paint stripping wheel.

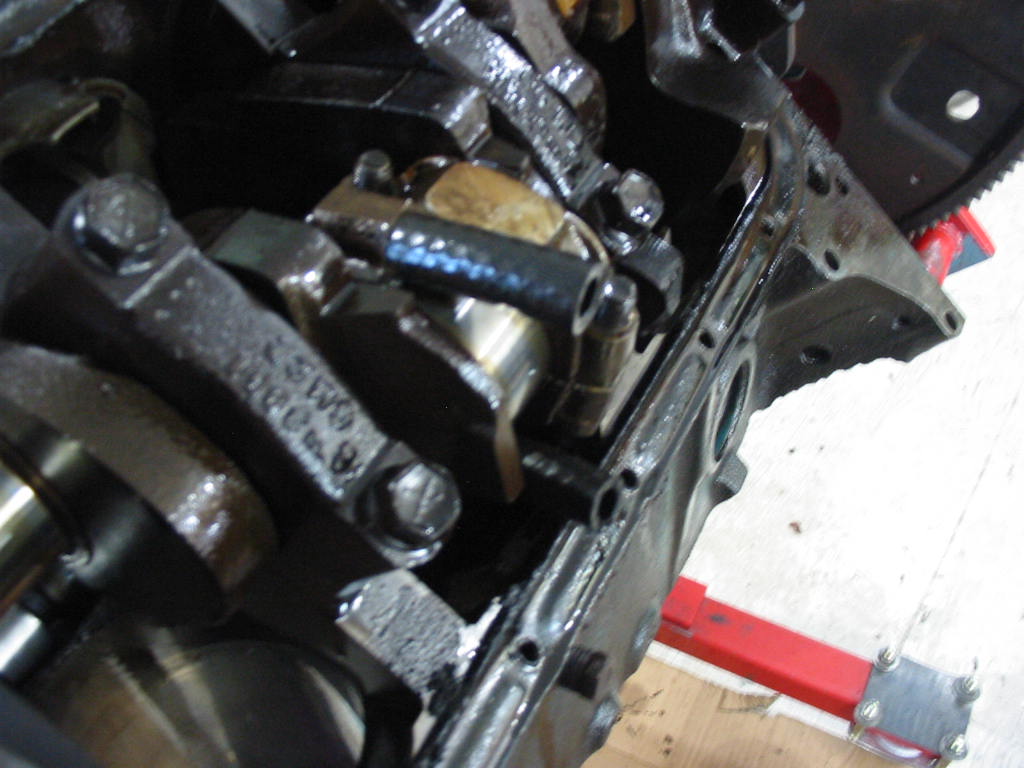

Old trick I learned years back is to put small lengths of rubber hose on the exposed rod bolts so they don’t accidentally gouge the crank journals as they pass by.

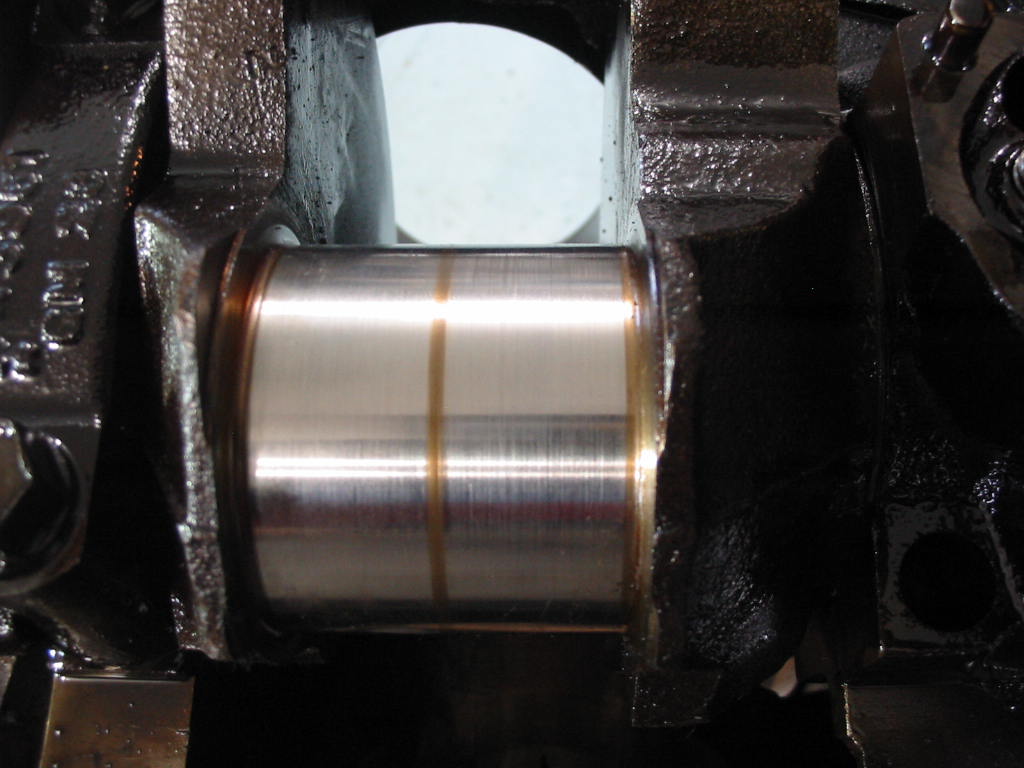

The crank journals look nice with just a bit of normal wear. I should be able to clean them up nicely with some 1500, 2500 and crocus cloth. I still need to do the measurements to see what I’ll need by way of rod journals and mains.

Next: more teardown and breakdown.