I’m a little out of sequence here. I meant to post this as the first in the series on the engine rebuild, but…..

Time to tear down the original 350 and see what needs to be done.

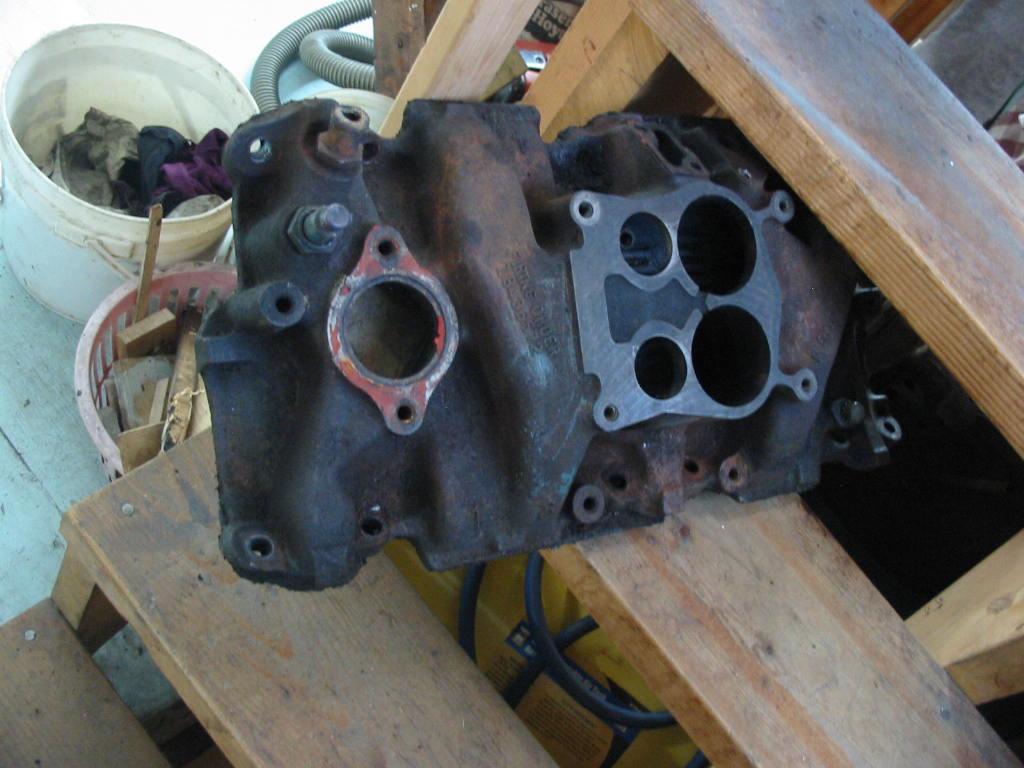

The original manifold will be replaced by an Edelbrock high rise – now on the 305 in the Chevy. I will keep it for whoever buys the car just in case they want to go back to the original intake setup.

The lifter valley looks nice and clean. Not much in the way of sludge. I did run some Seafoam cleaner through the system and that may have helped. The rust colour is not rust, but the reddish oil deposit from heated oil on hot engine parts.

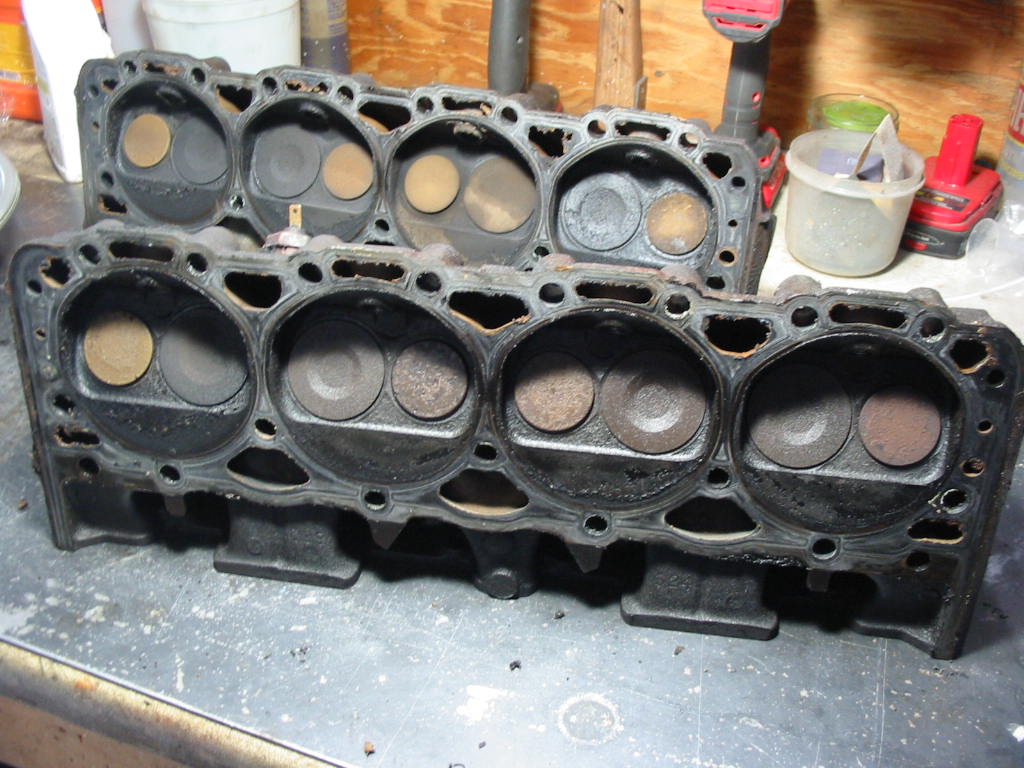

Looks like all the cylinders are firing pretty good except for the one on the back head, far right. These heads are GM462824 units. They are the light casting type. I don’t want to go through the whole process of doing a valve job and magnafluxing only to have them split sometime down the road. I do have a set of Mexico GM88417368 crate engine units with the same 76 cc combustion chambers and the same valve size. I’m planning on using them.

Lots of carbon and there is actually a chunk out of the intake valve (arrow).

Turns out it was another intake valve that was burnt (leftmost valve) and causing the continuous misfire that was so irritating. The next one was chipped, but seems to still be firing. The next valve shows that the valves were working their way into the head. Likely caused by high speed driving with unleaded gas – ’79 heads did not have hardened seat areas. The exhaust valves show a lot of carbon (far right). Not sure why

I’m keeping all the push rods and lifters in order just in case…

Pan off and all looks OK so far.

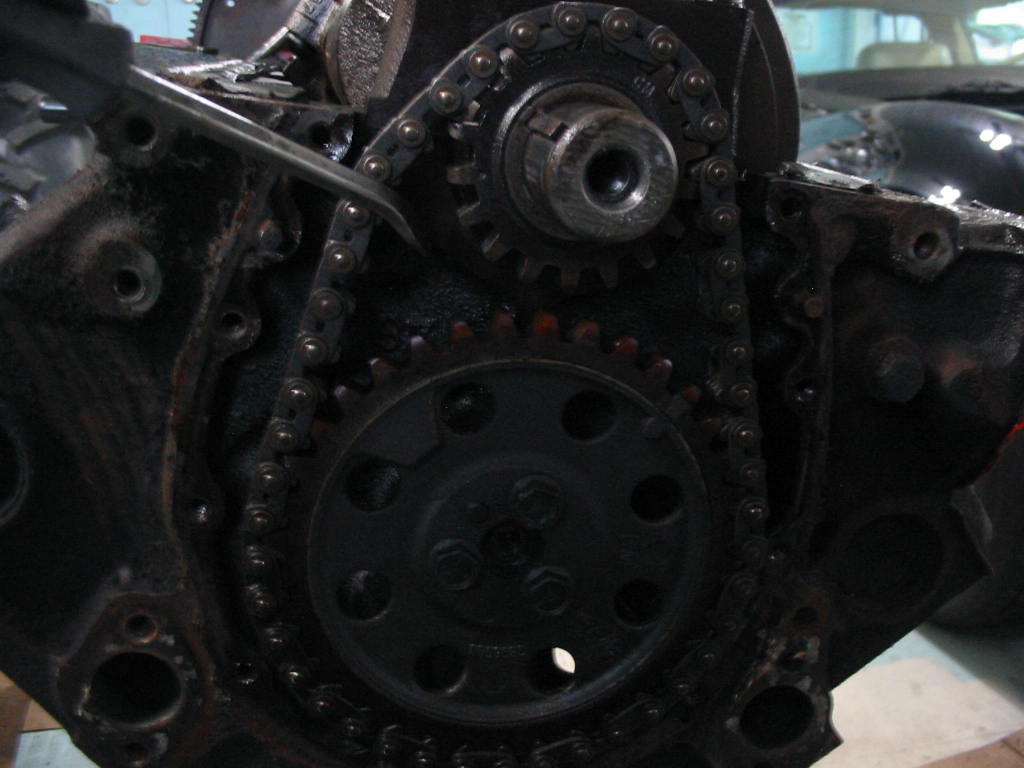

Harmonic dampener and timing chain cover off revealing a somewhat stretched timing chain.

Next: more on the tear down.